🌍 Electric Road Systems, towards decarbonising road transport

🌍 Electric Road Systems, towards decarbonising road transport

For its session on 19 June, Futura-Mobility, speakers, and guests explored the progress of various electric road system (ERS) projects in Europe, the technologies involved, together with the wider role of ERS in decarbonising road transport.

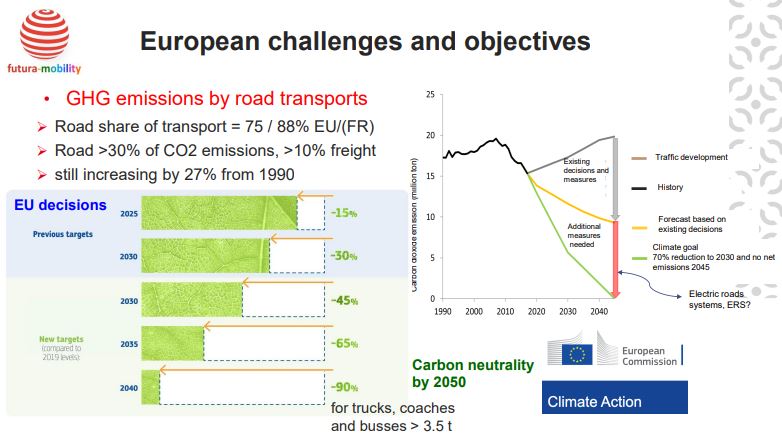

“The latest EU decision aims to reduce road transport emissions by truck, bus and coaches by 45% by 2030, 65% by 2035, and 90% by 2040 to reach carbon neutrality by 2050,” points out Bernard Jacob, senior research adviser, general engineer of bridges and roads, Université Gustave Eiffel and secretary of TC2.3 (freight), World Road Association (PIARC, see box).

Seventy-five to 80% of goods in the EU are currently transported by road – “the only sector where emissions have increased since 1990 because of rising traffic flow,” adds Mr Jacob.

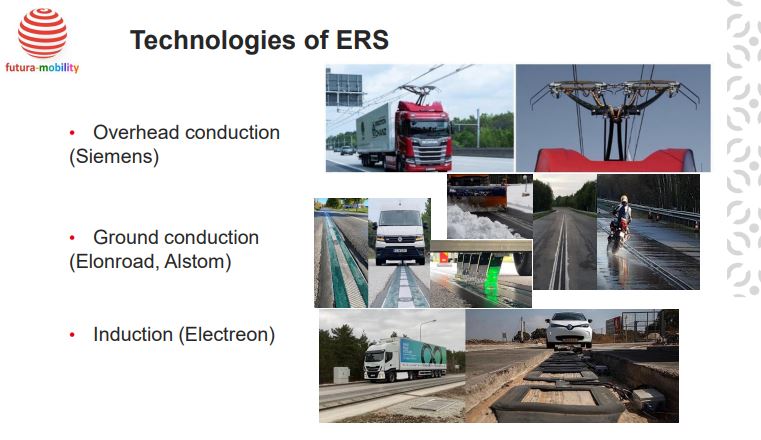

Given this urgent need to decarbonise road transport, ERS – delivering electricity to vehicles in motion – is one, among other pathways being explored. Based on the fact that electricity is easy and cheap to transport but difficult to store, delivery as for rail and metro systems in service today could now be applied to the roads. With this perspective in mind, the main technologies being explored are overhead conduction, ground conduction, and induction.

Given this urgent need to decarbonise road transport, ERS – delivering electricity to vehicles in motion – is one, among other pathways being explored. Based on the fact that electricity is easy and cheap to transport but difficult to store, as for rail and metro systems since the early 20th electric current could now be delivered on the roads. The main technologies being explored are overhead conduction, ground conduction, and induction.

Other pathways to decarbonising the roads include biodiesel, biogas, hydrogen and e-fuels, plus battery vehicles and charging stations.

Today, 7 to 8% biodiesel is introduced into standard diesel for road transport. But the agriculture and food sectors will always be competing with transport for supplies. Biogas (biomethane) is produced from organic waste but the amount available is limited. However, specifically in France, the government is aiming to increase annual production from its current 11.6 TWh (terawatt-hour) to 30 TWh by 2030. Nevertheless, it remains to be seen how much of a role biogas will play in covering the needs of the roads to meet EU emissions targets. In the transport sector, biomass should clearly be kept for modes that don’t have many alternative fuel choices, like flying for instance.

“Biodiesel and biogas are incomplete and intransient solutions,” reckons Mr Jacob. “They are easy to implement now but they won’t do the job over the long term.”

Several years ago, hydrogen was hailed as an energy of the future, and it may well prove to be the case. Yet M. Jacob, for one, isn’t convinced, citing its low efficiency with regards electrolysis and competition with industry for supplies. E-fuels are also limited because of “even lower efficiency than hydrogen across the whole chain and relatively high prices.”

“Hydrogen and e-fuels are convenient for a niche market and costly solutions for trucking,” states Mr Jacob.

Batteries and charging stations. Electrifying heavy duty vehicles with batteries and installing charging stations along the road network is an incremental solution that can be introduced now, without limitation. However, mega charging stations will be needed to meet demand, there are issues with the cost and weight of batteries for trucks, the need for critical materials for the batteries, the durability of the batteries and their recycling. “When you consider that 80 to 90% of vehicles will be fully electrified by 2035 in the EU, we’re going to face a big problem meeting demand for recharging stations, with a lack of space and power”, points out Mr Jacob. “Nevertheless, this solution is vital for driving uptake of electric trucks,” he advocates.

ERS in Europe and France

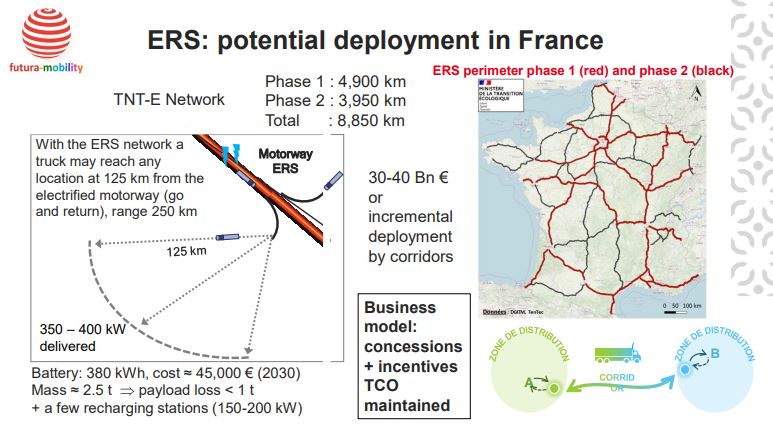

In Europe, the ERS concept envisions having some but not all motorways equipped with ERS systems. On this basis, specifically in France, a network of 8,850km could potentially be deployed (see slide below) – according to studies carried out for the French Ministry of Ecology in 2021. “After sizing, we knew what traffic was on what part of the network, and estimated the power needed on each segment for trucks,” explains Marc Raynal, development director, Infrastructure, Transport and Mobility division, Cerema (French Centre for Studies on Risks, the Environment, Mobility and Urban Planning). “We assessed that an 8,800km network is the economic optimum for trucks.”

Such a network would allow truckers to reach anywhere in France just 125km away from an electrified road. With a 250km battery range, it would be possible to reach any destination then return to the ERS road on a single charge. Also key to the concept: “although the same quantity of electricity will be needed as for charging stations, it will be spread along the motorways 4 megawatts every km, rather than having it in concentrations of around 50 megawatts,” explains Mr Jacob.

According to Cerema’s figures, the cost for trucks using this 8,850km ERS network – about 0.3 to 4 euros per km per truck – would work out at almost the same cost as for diesel trucks on the roads today. On the other hand, a battery range of 130km, instead of the 450 or 750km currently needed by trucks using charging stations, with or without recharging during the journey, would be sufficient for a 15,000km network, which has not been retained at this point.

The benefits of ERS are obviously savings in terms of the size and range of batteries needed by ERS trucks, as well as a significant reduction in the critical resources needed (to build the batteries) and GHG emissions from the batteries used (whole life cycle analysis).

Furthermore, total cost of ownership (TCO) is a key selling point for ERS. Less battery weight means more payload. Indeed, analysis by the French National Road Committee (Comité national routier, CNR) shows that ERS could be the most positive TCO for vehicles compared to other decarbonising solutions.

“At Scania we know that ERS is a fantastic and highly efficient opportunity for reducing C02. If you electrify 3% of the roads most heavily used by trucks, you can cut C02 emissions by 60%, which is huge,” enthuses Gilles Baustert, director marketing, communication and public affairs, Scania France. “However, we also know that our clients, hauliers, can’t be the adjustable part when it comes to costs and investments– they have to be able to earn their living.”

The costs of ERS for hauliers must absolutely be taken into account, agrees Hélène Quévremont, technical director, environment and innovation, Organisation des Transporteurs Routiers Européens (OTRE). Especially when it comes to the electricity and electric trucks. “Since the margin in transport is very low, around 2%, hauliers need price stability for electricity. Also, right now an electric truck cost three times more than a diesel one.”

“The savings from ERS will not come from the infrastructure but from the batteries on the lorries using this network,” adds Mr Raynal.

The cost of deploying the projected 8,800km ERS network in France is estimated between 30 and 40 billion euros. A significant investment, but not requiring any state funding with the concession business model, for instance.

Pitches by key solution providers

- Ground conduction

👉 Alstom has developed a ground conduction solution (APS, Alimentation par le sol), derived from the solution implemented for tramways, in operation first in Bordeaux 20 years ago, and then in several other cities.

A feeding track integrates a succession of 11-metre-long segments in two parallel lines (one for the supply, the other for the return current). It is installed in the middle of a traffic lane in the upper pavement layer (6cm deep). The feeding track segments are activated under the equipped vehicles while the other ones are switched off. The vehicle is equipped with a current collector device, which deploys automatically when the vehicle is above the rail. The current collector shoes are supported by an articulated arm that follows the segments, regardless of the lateral position of the vehicle in its lane. The segments are powered by electrical substations installed every 1km and can deliver up to 500 kW per truck.

The first tests were carried out on a Volvo test track near Gothenburg in Sweden, between 2012 and 2016. Alstom then improved the system to increase the power transfer level, the skid resistance, and to mitigate current losses in presence of salt in winter conditions.

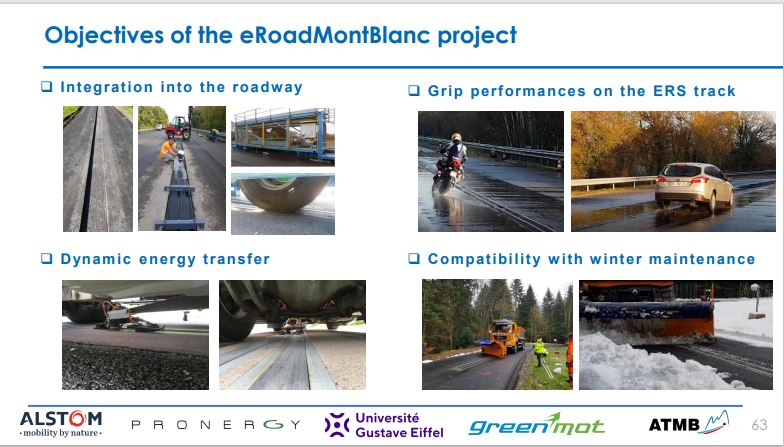

A demonstration project, eRoadMontBlanc, has been underway in France since 2023, with a test track at Transpolis, near Lyon, in 2024, and a first permanent electric road section planned on the RN205 in 2025.

👉 The Swedish start-up Elonroad provides a conductive ERS solution embedded in the road. It comprises short, one-metre-long segments where the power is switched on. Electronics in the road transmit the energy used for each vehicle, plus it is also possible to control who can charge (if drivers have paid their bills) and regulate peak power.

“One of the benefits of our embedded rails is that they have internal power feed, so you only need cabling from the power station once every second kilometre from the side of the road. This makes construction easier and faster,” explains Dan Zethraeus, CTO, founder and head of innovation.

The on-board charging equipment comprises a sliding contact (pick-up), fitted under the vehicle, plus a charger and battery. To ensure steady and perfect charging, with the help of cameras to ensure correct positioning, the pick-up adjusts to always follow the rail.

In addition to building two test roads in north and south Sweden, in June 2023, the start-up built a new road in Belgium, just outside Brussels. It is also participating in the Charge as you Drive project in France.

- Inductive charging

👉 The technology by Electreon “offers a complete charging solution, by combining wireless static and dynamic charging, to address all vehicle needs,” says product manager Itai Koren. “The strengths of our technology lie in it being completely modular and vehicle agnostic – it can support any vehicle type.” Furthermore, Electreon provides a software platform for managing the entire infrastructure – both for the charging side (ground assembly) and for electric vehicle fleets.

In 2020 the company installed 1.6km of pilot ERS in Gotland, Sweden, to demonstrate the multiple use cases for its solution. Since then, it has over 20 projects running worldwide, including in Italy, Germany, the US, Israel, and France, where it is involved in Charge as you Drive project to deploy dynamic charging on the A10 highway.

- Catenary system

👉 With decades of experience in the rail sector under its belt, it makes sense Equans is supporting the catenary system solution for ERS “For ERS we are offering a mature solution based on the same electrical design as for railway catenary systems,” says Gaëtan Texier, international development, Equans. “We have the experience and know-how for building catenary systems. whatever the environment.” The company has been running ERS pilots in Germany since 2018, “and all are working fine,” reports Mr Texier.

Note, the catenary system is the only ERS solution that doesn’t function for lighter vehicles.

ERS state of play in Sweden – “costly, yes, but interesting”

“The basis for electrifying road traffic in Sweden is static charging,” explains Jan Pettersson, programme director, Trafikverket (Swedish Transport Administration, Ministry of Transport). “But we believe we need a compliment to this static charging, so ERS could be one piece in the puzzle. We are also analysing other technologies and solutions like hydrogen and battery swapping.”

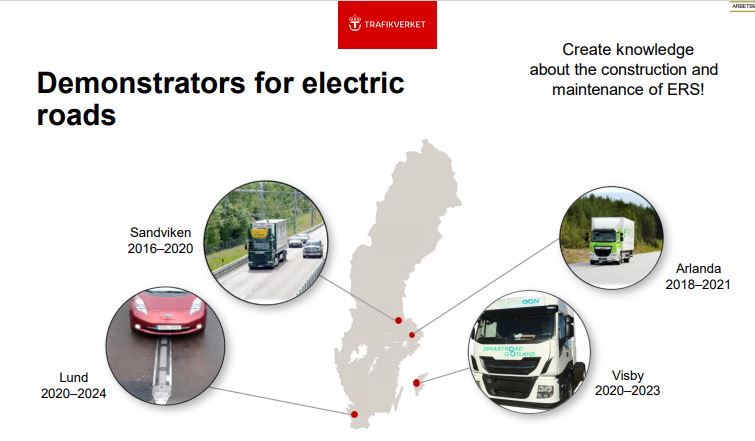

To gain knowledge on building, maintaining, and operating ERS, Trafikverket has tested four technologies in real traffic situations at demonstration sites across Sweden. As part of these demonstrators, between 2016 and 2020, Siemens and Scania put all the technologies through their paces. “The testing in Sweden, now dismantled, proved that the technologies work perfectly, even in harsh weather conditions,” confirms Mr Baustert from Scania France.

As a next step, Trafikverket is now preparing for a procurement phase. Due to be launched at the end of 2025, the plan is on the E20 motorway between the towns of Hallsberg and Örebro – both located in the middle of the logistics triangle between Stockholm, Gothenburg and Malmö. The charging method for E20 hasn’t yet been decided but the three types of charging on the table are catenary, conductive (ground-based), and inductive.

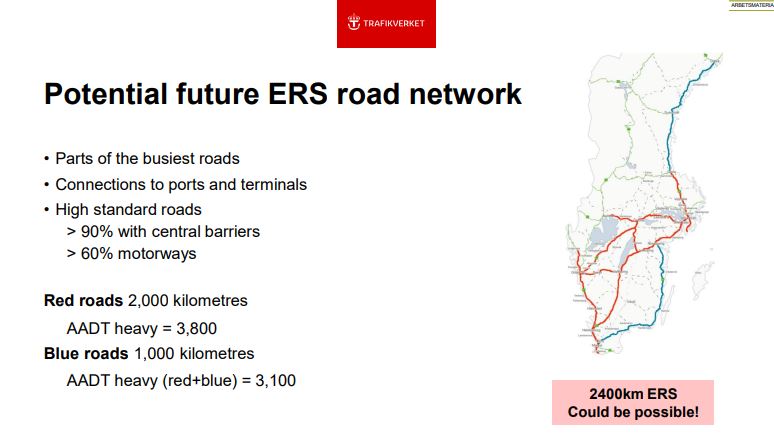

Looking further ahead, “our analysis shows that building 2,400km of ERS in two phases could be socially-economically positive. This is the plan for Sweden,” sums up Mr Pettersson.

The World Road Association (PIARC), the world’s biggest organisation for road administration, currently has nearly 3,000 members (governments, regional authorities, companies, universities, individuals) in 142 countries. “There is big interest globally for ERS among National Road Authorities,” confirms Mr Pettersson from Trafikverket, a PIARC member.

ERS in Germany – national and transnational projects

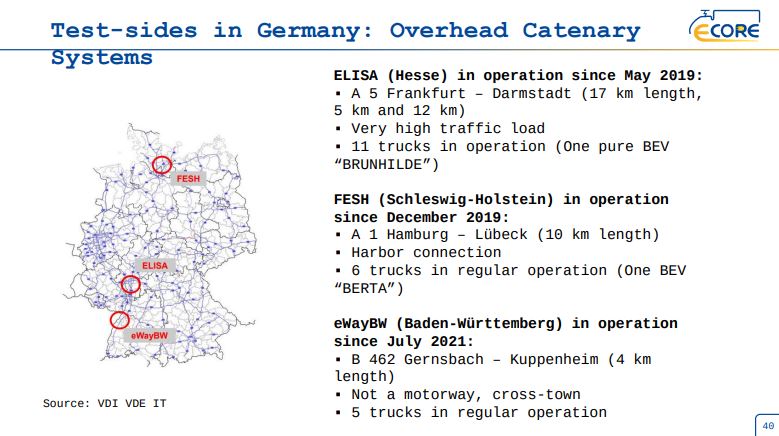

Germany has also spent the last decade experimenting ERS technologies, mainly overhead catenary systems, and recently induction. Three test tracks installed by Siemens have been running nationwide since 2019 and 2021 with overhead conduction, the longest of which is 17km, and one with induction (duraBAST) near Cologne.

In parallel, ERS initiatives ongoing in Germany include EnERSyn (2022-2025), which is assessing the potential synergies of ERS with stationary charging technologies, and E-Core, a transnational, technology neutral project that kicked off in October 2023 and will run for three years. Its participants are studying various technologies for an electrified corridor combined with stationary charging (so a combination of dynamic and stationary charging) for heavy trucks (Rotterdam to Budapest) through the Netherlands, Germany, Austria, and Hungary. “All the studies by the different partners from these countries combined should lead to an EU corridor concept,” explains Giverny Knesevic, scientific advisor, Institute for Climate Protection, Energy and Mobility, IKEM.

With its test tracks due to end in the coming months, what’s the next ERS move for Germany? Dismantle or transform into permanent ERS roads? “There’s lots of discussion right now in Germany,” says Ms Knesevic.

For the E-Core project team, boosting the visibility of ERS and its different technologies at EU level is one of its priorities going forward. “To date, while ERS is part of the alternative fuels regulation, it is not recognised as an equal alternative infrastructure like stationary charging,” points out Ms Knesevic.

Dynamic charging by induction – the Arena del Futura project, Italy

The Italian pilot project Arena del Futura is testing Electreon’s technology for dynamic charging by induction. The team (see box) has measured the efficiency of the system on a purpose-built test circuit by A32 – BREBEMI using a light (Fiat 500) vehicle and a 12-metre electric E-WAY bus from IVECO Bus, retrofitted with the necessary connectivity and recharging technology. The results showed:

– 80-87% energy transfer efficiency for dynamic charging, depending on how the vehicles are aligned with the coils installed under the asphalt;

– 91-92% efficiency for static charging.

A32 Highway – BREBEMI, ABB, Electreon, IVECO, IVECO BUS, Mapei, Pizzarotti, Politecnico di Milano, Prysmian, Stellantis, TIM, FIAMM Energy Technology, Università Roma Tre, Università di Parma, Vigili del Fuoco and Ministry of the Interior – Polizia Stradale.

Organisations, industrial partners, universities, and international institutions on board Arena del Futura

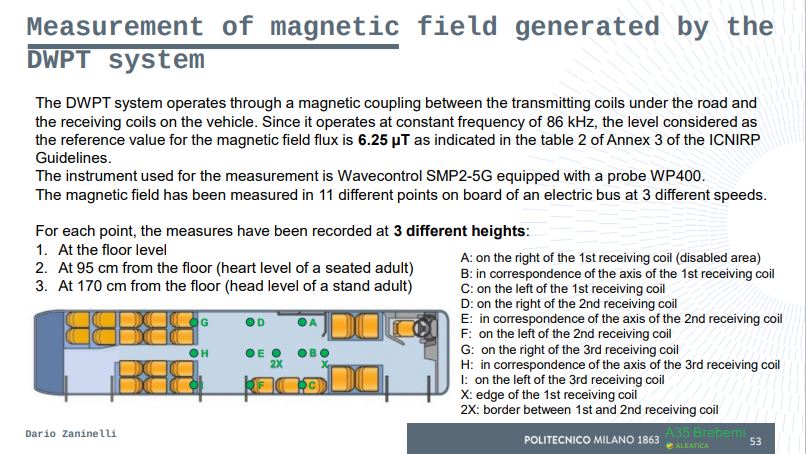

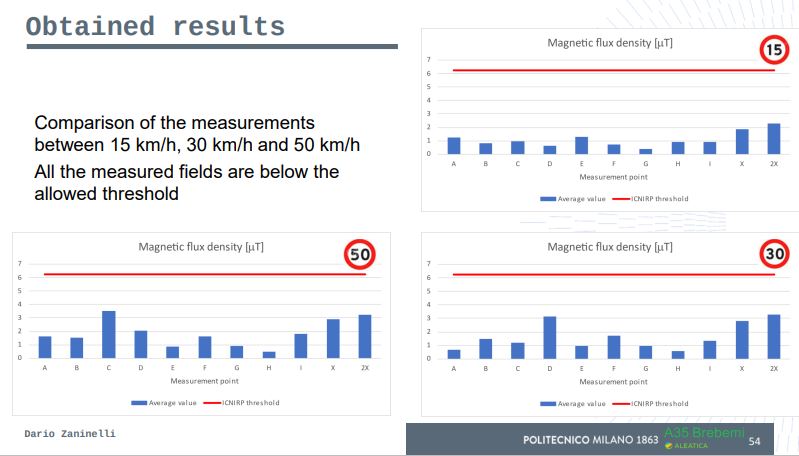

“We have also measured the magnetic flux in the bus, depending on the height from the floor at different spots on board and at different speeds (15, 30, and 50 km/hour),” explains Dario Zaninelli, full professor, energy department, Politecnico di Milano. Here the findings showed levels below the permitted threshold, according to the EU directive, for human exposure to electromagnetic fields.

“We are now testing the system safety in the case of road accidents, together with the Italian Fire Department, as well as the performance on commercial vehicles for distributing goods in urban areas,” sums up professor Zaninelli.

eRoadMontBlanc – onward and upward

A collaborative project for a ground level, contact supply system, eRoadMontBlanc, launched in June 2023 in the Chamonix-Mont Blanc valley, has ambitious ERS objectives: to clock up 50,000 km in ERS mode; to be the first electric road in the mountains with a 4% average gradient; to provide a power transfer of up to 500kW for HGVs. “The level of power transferred regardless of the number of heavy goods vehicles per km is a real differentiator and a key argument in favor of the APS solution,” points out Patrick Duprat, infrastructure competitiveness and R&D director, Alstom.

Its consortium of five French partners comprise Alstom as the ERS road supplier, providing its APS (Alimentation Par le Sol) ground supply system; Pronergy, a manufacturer of onboard power electronics who is supplying vehicles for the project; Université Gustave Eiffel, playing several roles in testing and R&D for the road surface, the creation of digital twins, building test tracks and assessing the technology; Greenmot, a specialist in retrofitting industrial vehicles, who is supplying one heavy goods vehicle; and the motorway concessionary ATMB which will host and operate the ERS section on its network.

Phase one, ongoing, is building a test track and using two test vehicles to validate all the service functionalities (plugging in trucks, payment methods, etc) and safety – in order to obtain authorisation to go on the open road. Next, in 2025, a first permanent ERS motorway section will be operational between France and Italy, including a 1km stretch in the Mont Blanc tunnel, at an altitude of 1,000 metres.

“The aim is to reach maturity level 7 or 8 with this demonstration on the open road,” sums up Mr Duprat. “With this project we plan to build the first permanent electric road for operation with three types of vehicle to demonstrate interoperability. It will be the first electric road with up to 200 ERS vehicles per day and also the first built in the mountains with a steep incline.”

Charge as you Drive

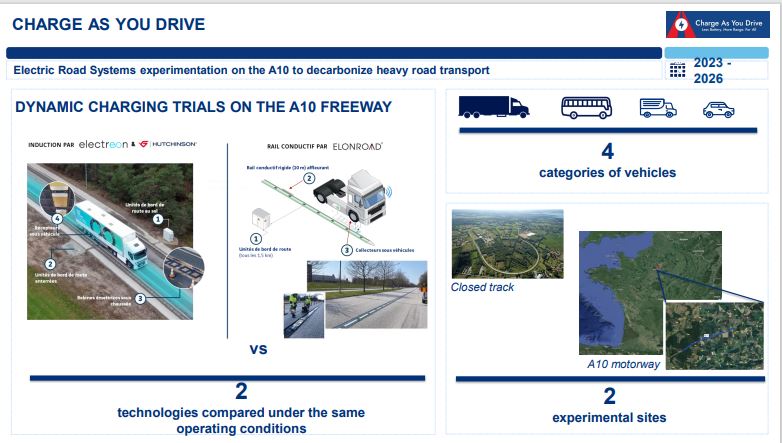

Two technologies, four categories of vehicle, and two different test sites. The Charge as you Drive project in France, aims to demonstrate ERS on the A10 motorway southwest of Paris. Running from 2023 for three years, it follows a call to tender by BPI France (French public sector investment bank) for projects to decarbonise mobility.

The winning consortium and associate members (see below) will equip the first motorway sections over longer distances, for commercial use, with a view to a wider deployment of ERS across the French motorway network – as proposed in L’autoroute électrique, a study released in 2021 by the French Transport Ministry.

“ERS is a solution for bridging the gap between SNBC 2* and FitFor55 targets by complementing electrification of HGVs,” says Nicolas Hautière, director, COSYS (components and systems department), Université Gustave Eiffel.

Note: *SNBC 2 is the National Low Carbon strategy outlining the French roadmap for reducing greenhouse gas emissions (GHG). FitFor55 is the new 2021 European Climate Law targeting a 55% decrease in greenhouse gas (GHG) emissions by 2030).

Wait and see

The speakers at this Futura-Mobility session agree that ERS has the potential to help decarbonise road freight transport, and that the technologies are now proven. So what’s next?

Funding and decisions for one thing. “Private investment, for instance, would help kick things off faster than waiting for state backing, as well as supporting the gradual electrification of the target motorway roads,” believes Mr Jacob. But there’s more besides. Talks at European level are also needed to try and agree on a single or at least compatible systems. Indeed, deciding on which technology (ideally one, two at most) to use everywhere in Europe going forward is crucial. As Gilles Baustert points out, Scania can manage two – ground and overhead conduction, one on top, one under the chassis – on the same truck. But not all of them. Furthermore, the more the vehicle is equipped, the heavier and more expensive it is and more energy it will consume when driving.

“At Equans, we are currently working on funding to build the solution and decisions at government, country and European levels regarding aspects such as compatibility and who is investing what,” adds Mr Texier.

In the meantime, wait and see seems to be the name of the game. OEMs like Scania are holding on for the infrastructure. ERS pioneer Germany is “observing its neighbours Sweden and the Netherlands, as well as France with the different ERS technologies.” Many small and medium sized haulage companies are sticking with diesel trucks for the time being, until longer-term decisions are taken.

Yet ERS could well be part of tomorrow’s roads. “It is a complementary installation to in-station charging, and the best way of solving the land issue for new, e-truck parking areas,” points out Mr Texier.

“The ERS is a brick, a component of the road of the future,” projects Mr Hautière. “This road will be safe, connected, and designed for clean mobility/e-mobility.”