🇨🇭 Switzerland, innovation territory for better performing energy systems

🇨🇭 Switzerland, innovation territory for better performing energy systems

At EPFL Valais, Energypolis alone is home to 29 laboratories offering a complete value chain – from fundamental research to bringing innovative solutions to market, combining research and business. The Industrial Process and Energy Systems Engineering (IPESE) lab, headed by Professor François Marechal, specialises in optimising energy systems in their context, working at different scales: from a factory or transport system to a neighbourhood, city or even a country.

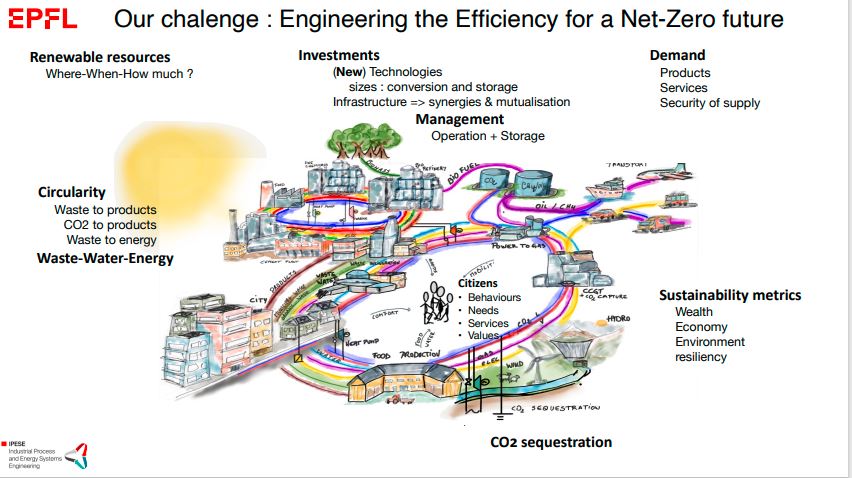

In today’s energy world, geopolitical tensions have rendered oil stocks for energy management unpredictable. The criteria for decision making about energy need to be reviewed to include aspects such as access to the resource or the resilience of systems. Furthermore, issues like material resources, the circularity of waste (waste to product), plus carbon as a resource and recyclable element, must be explored.

Faced with these challenges, together with the net zero goal, Professor Marechal and his team of researchers are developing decision-support methods for system engineering with waste – water – energy foremost in mind. Their computer platform Osmose, for instance, provides decision support for integrated energy system design to boost efficiency in industry and renewable energies.

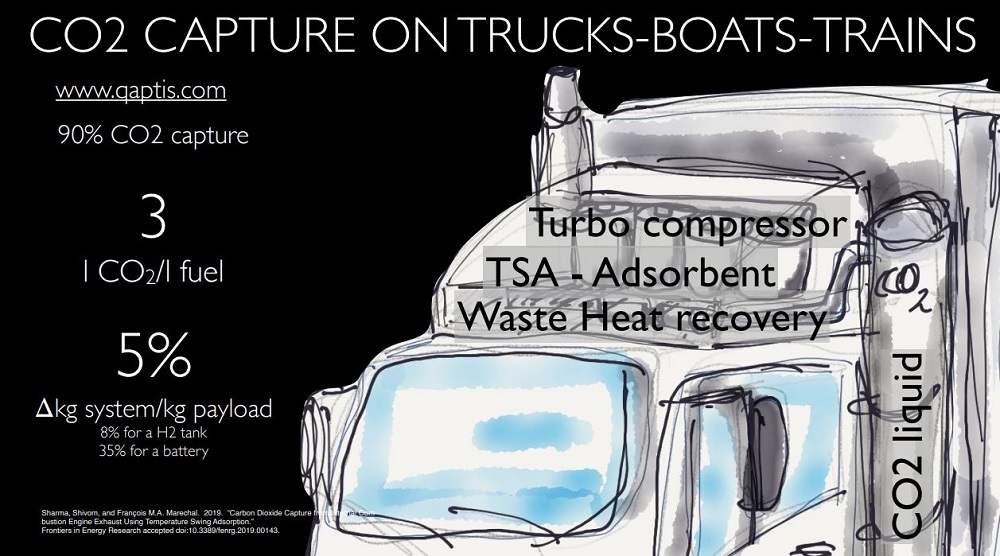

Specifically for the mobility sector, the lab is working on a project with manufacturer Novelis, to produce aluminium for the auto industry that doesn’t generate CO2 emissions. Another initiative, in collaboration with the EPFL spinoff Qaptis, is focusing on capturing and recycling CO2 from heavy duty trucks (plus ships and trains) to reduce carbon emissions in the freight transportation sector. This innovative solution involves retrofitting existing trucks with a system behind the cab. The CO2 emitted from the truck exhaust is captured and stocked as a liquid on the vehicle, then transformed into fuel at a service station. Tests reveal it is possible to capture up to 90% of the C02 emitted.

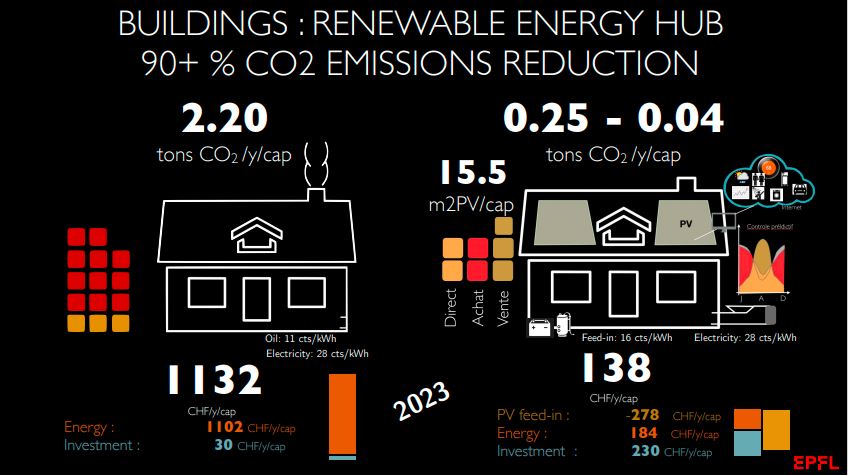

Renewable energy hub and e-vehicles (EV)

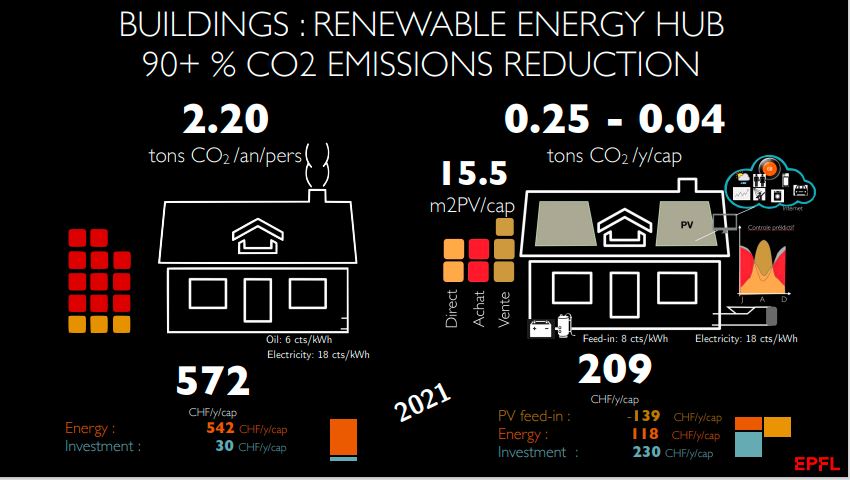

“Society is transitioning towards a less centralised and cheaper energy system,” says Professor Marechal. Having batteries in cars in the garage, solar panels on the roofs of homes, plus the emergence of new services like the heat generated from data centres, for instance, are all bringing energy production closer to home.

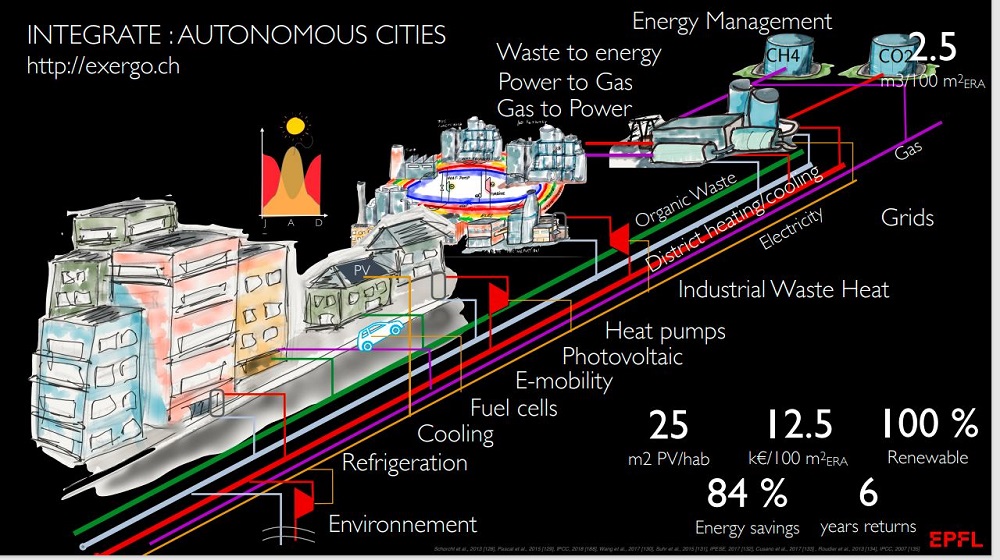

In this shifting context, Professor Marechal and his team of researchers are working to streamline energy consumption in towns. They are exploring the ways and means of designing optimised and local systems that collect energy lost to the environment and channel it where needed, based on the principles of thermodynamics. The lab is studying, every possible technological solution (more advanced heat pumps and fuel cell technology, biowaste, etc.), together with interconnectivity models, to create a global system (see slide below).

Such integrated cities, with renewable energy hubs and micro grids, will gain in energy autonomy and so need to draw less from the national grid. “For this more localised, autonomous system approach, we also need to invest in networks and storage,” points out Professor Marechal.

Households should benefit not only by reducing their energy bills but also, in Switzerland, by having the opportunity to resell any excess energy to the grid at a profit. So the approach is extremely interesting, especially given the high cost of energy in Europe today, which is expected to continue for the near future.

Electric vehicles (EV) with their on-board batteries, play a key role in this local energy ecosystem. Indeed, buying an EV brings greater flexibility and so less dependence on energy sourced externally. The owner of an EV is, in actual fact, buying a battery for the grid, so a storage capacity. This configuration completely redefines the relationship with the energy system. Any battery in a car will end up in the home when its performance drops belong a certain level, i.e. 10 years in the car, 10 years in the home. “So we’ll double battery capacity in 10 years. In 20 years, buy another one,” sums up Professor Marechal. “But in actual fact, we’ll be re-using the batteries.”

Swiss Battery Technology Centre – open innovation for next-generation batteries

At Switzerland Innovation Park Biel/Bienne (SIPBB, see box) much of the research by the Swiss Battery Technology Centre (SBTC) focuses on recycling and dismantling batteries at the end of their service life. It is an academic partner of companies for research and development projects.

“Over the last 10 years we’ve seen a lot of vehicle electrification, especially for heavy duty trucks in mining and agriculture since, more often than not, these sectors can benefit from wind and solar energy,” says Christian Ochsenbein, head of the SBTC.

At the same time, sales of EVs are certainly growing: worldwide, over 10 million were sold for the first time in 2022, and more are expected to be sold between 2026 et 2028 than combustion engine vehicles. In Switzerland, the national Elektromobilität roadmap is targeting EV market shares of 50% by 2025.

“The EV market is growing but requires a lot of rare metals, especially lithium, demand for which, according to the IEA [International Energy Agency], should increase x40 between 2020 and 2040,” warns Mr Ochsenbein. “This leads to thinking about next-generation batteries. We need a long-term solution.”

The SBTC is a founding member of iBAT, an academic-driven network of research, industry, and government. With its 70+ members, iBAT promotes the study of battery technology along the entire value chain – from production to use and recycling of batteries.

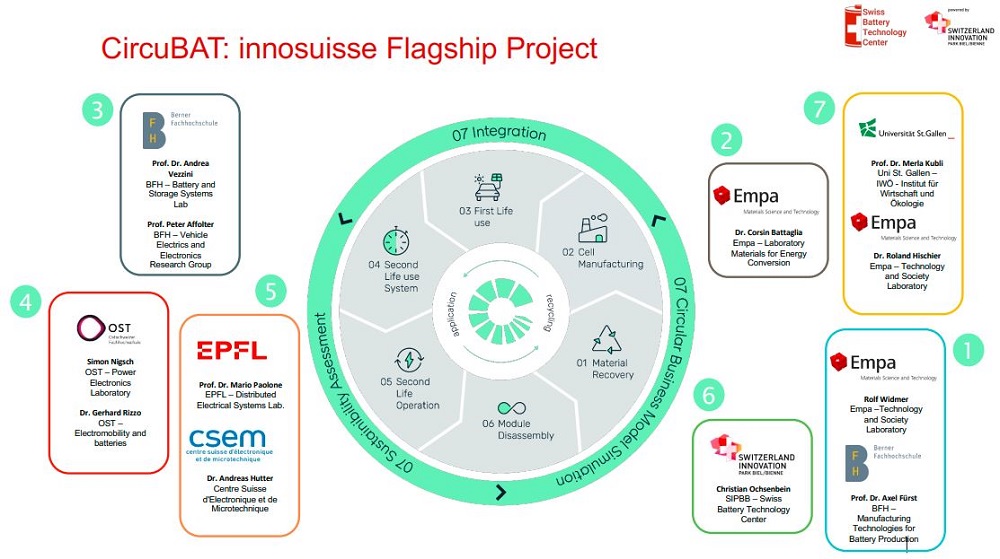

CircuBAT for eco-design batteries

A flagship project at the SBTC, CircuBAT (Circular Economy Lithium-Ion Batteries) is studying how “to make batteries better at the cradle stage to enable more efficient recycling and extend their service life,” explains Mr Ochsenbein. “We are exploring the seven work packages together with industry, from start-ups to corporate.”

The project aims to establish guidelines designing new battery packs that take direct disassembly and recycling into account. It also seeks to make electromobility more sustainable and minimise the CO2 footprint of lithium battery systems throughout their lifetime.

CircuBAT is working on disassembly using an automated robotic process based on reinforced learning: the robot is trained in disassembly skills by experimenting in the SBTC’s metaverse BattREverse. “There are advantages of using this automated robotic approach, like higher throughput, enhanced accuracy and repeatability, and human resource optimisation,” points out Mr Ochsenbein.

In parallel, robotic disassembly presents plenty of challenges too: many shapes/types of parts that need to interact, complex connectivity between parts, or tasks where human intervention is unavoidable, amongst others. Hence the reason the SBTC has started a lighthouse project to overcome them, based around artificial intelligence (AI).

The SIPBB is part of a private, Swiss non-profit organisation made up of six sites nationwide. Its R&D centres demonstrate how to practically apply new technologies and thus importantly close the gap between research and industry. Funding, 90% private, is sourced mainly from industry, Public Private Partnerships, the canton of Bern, and the city of Biel. SIPBB’s Swiss Smart Factory, a working platform with startups and industrials, is the first model factory for industry 4.0 in Switzerland.

Energy Storage Research Centre for better battery knowledge and use

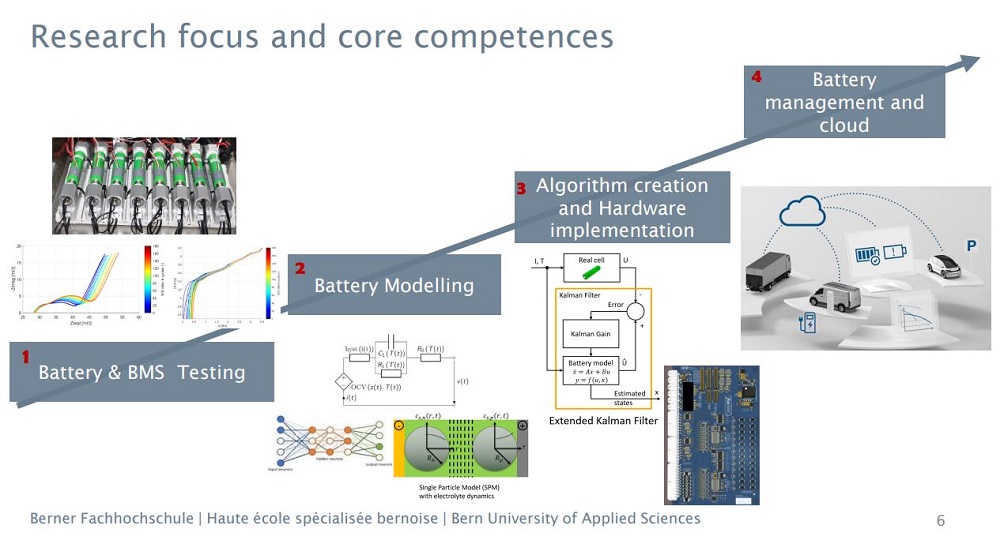

The SIPBB is also home to the Energy Storage Research Centre of Bern University of Applied Sciences. This Centre has one of the most advanced storage research laboratories in Switzerland. Financed by companies and cantons, its work, which ranges from research to product development, focuses on researching electrochemical energy storage solutions for energy supply and mobility.

For batteries, testing, modelling, creating algorithms and management are the four core activities. Testing is wide ranging and includes aspects such as battery management systems (BMS), with safety foremost in mind, and degradation: for instance, taking into account the two main types of battery degradation – cyclical (charge/discharge) or depending on the environment (state of charge, conditions) – diagnostics are performed to understand the causes of degradation.

With practical applications in mind, the Centre has developed a method for obtaining statistical analysis of batteries to establish their real, as opposed to marketed, performance.

Another example, in the case of electric bikes, users always charge their batteries 100%, yet tend to use just 50% before recharging again to 100%. Work by the Energy Storage Research Centre reveals it would be more cost saving to charge up to 80%.

This better understanding of battery behaviour would obviously benefit operators of large fleets of buses or company vehicles: they could choose the right batteries (most appropriate chemistry and cells) for the right use cases and optimise their usage cycles (charge/recharge) to make more cost-efficient operating decisions.

Taking this line of research one step further, the team has even developed an open-source model, called the ‘open-sesame model’, that provides companies with a first level simulation of the lifetime and behaviour of their battery, according to the user’s own power and temperature profiles.

As well as studies requested by its partners, the Energy Storage Research Centre produces reports on the state of knowledge of Bern University of Applied Sciences: news on the next updated issue will be shared on social media.

Tip of the iceberg

Research and testing in labs, applications in the field, and start-ups with their fingers on the pulse… Western Switzerland is very much at the forefront of tomorrow’s battery technologies. The Futura-Mobility learning expedition caught a valuable glimpse of the activities ongoing in this field. Impressive indeed! Yet it was also obvious the two-day trip had revealed just the tip of the iceberg. There is certainly plenty more to explore and discover…

Met during the LEX, WattAnyWhere is a Franco-Swiss start-up founded in 2020 by engineers from ENSEA and Honeywell. At the intersection of mobility and energy supply issues, it offers an additional energy supply solution by obtaining electricity from biomass, independently of the power grid.

“Up until now, the focus has been on developing networks of EV charging stations,” explains Didier Roux, co-founder and CEO. “Now we’re wondering how to supply them without overloading the national grid.”

The WattAnyWhere generator converts ethanol into electricity for EV charging. Produced worldwide, ethanol is derived almost 100% from biomass. The infrastructure exists, is operational and efficient. Today, 80% of ethanol is used in internal combustion engines (E5, E10, E85 at the pump). ‘The sugar manufacturers CristalUnion and SudZucker (France, Germany) tell us there are no worries about producing ethanol,” says Mr Roux.

WattAnyWhere is initially eyeing the EV market “since it is already mature,” explains Mr Roux. “We then may target the construction sector, dockside power supply, or data centers.” And potential customers? Hypermarket chains like E. Leclerc and Auchan, which already purchase ethanol for integration into gasoline at their service stations. “Gas stations in supermarkets are likely to have huge power peaks if we install fast charging stations for EVs. But changing power categories will be complicated, expensive, and time-consuming.”

Right now, sights are set on France and Switzerland. Plus there is a 1st prototype – 5kW set to come out in 2024 – in the lab. Work is also already underway for the next, 50 kW. So the focus in 2023 is very much on developing prototypes, in particular with Leclerc. “We have a serious strategy to be the leader in the market,” sums up Mr Roux.